Frequently Asked Questions

J.R.’s Commercial Cleaning DOES NOT provide powder coating services. The questions and answers on this page are for information purposes only in order to help you better understand the powder coating process.

What is Powder Coating?

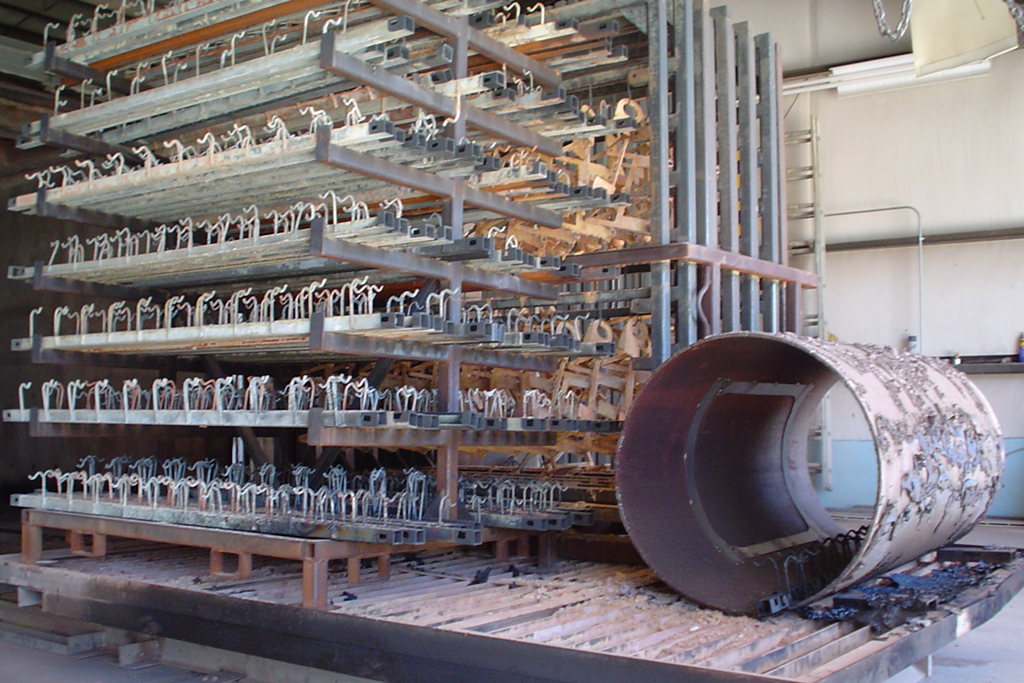

Powder coating is the application of a dry, powdered resin to a surface. The resin is typically a thermosetting (polyurethane, acrylic, epoxy, etc.) or thermoplastic (nylon, vinyl, etc.) resin which is electro statically applied to the surface of a part. Application is done with a spray gun or fluidized bed. The coated part is then heated and the melted resin flows to form an unbroken film. The electrostatic charge holds the powder particles in place while the part is cured in a 400-degree oven. The heat of the oven causes a chemical reaction to occur and the powder to cure, creating a highly durable finish. When cool, the film exhibits properties often exceeding those achieved by conventional painting methods.

Is Powder Coating Environmentally Friendly?

Is Powder Coating Durable?

What Can Be Coated?

Any metal object that can hold an electrostatic charge and withstand the heat of the curing process can be powder coated. Powder can be applied to intricate surfaces and still maintain a uniform finish across the entire piece. Powder coating is ideal for items such as:

- Industrial Fabrications

- Architectural Signage

- Trade Show Exhibits

- Metal Fencing and Railings

- Retail Displays & Fixtures

- Patio Furniture

- Motorcycle Frames Wheels & Parts

- Automotive Frames Wheels & Parts

- Off Road Vehicle Frames & Parts

- Bicycle Frames & Parts

- Antique Beds, Gliders & Chairs

- Large Bird Cages