Frequently Asked Questions

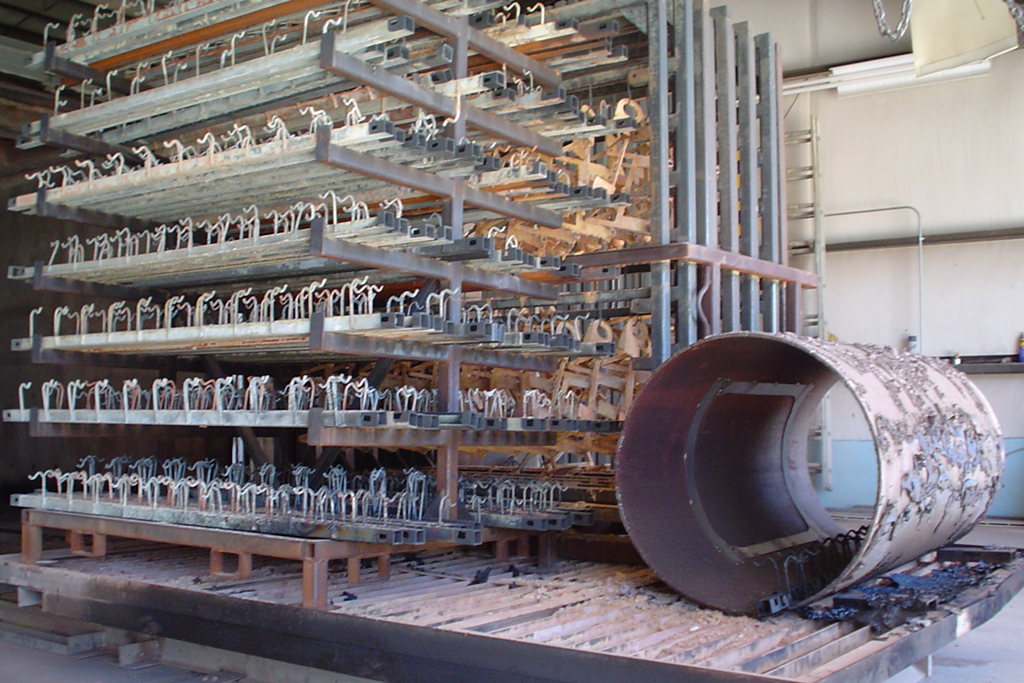

″I process faucets and fittings pieces in my galvanoplastic plant. These pieces are on racks that are repaired sometimes. The racks are painted with PVC to protect them from the electrolytic process. When I want to repair one rack, I have to remove the PVC paint. Now I am using chemical solvents, but their effluents are very difficult to treat. I was looking for information about the “hot-sand process”, but the supplier told me that is not convenient.”

Do you know another process to remove the PVC paint on the old racks?

You can burn off the PVC is a high temperature furnace. This is a very efficient and cost saving method that will remove all the paint and PVC from the metal rack. Many plating and paint shops burn the coating off their racks at very high temperatures so all that remains is an ash. J.R.’s Commercial Cleaning is able to clean all your racks in one batch with our large walk-in oven.

I've heard that Burn-off ovens cause damage to the parts that they clean. Will J.R.'s Commercial Cleaning Burn-off oven damage my parts?

Probably not. J.R.’s Commercial Cleaning Burn-off oven uses a patented method of heating called “Top-Down Heating” to control the temperature in the hottest part of the oven. Our competitors’ bottom-fired ovens put the heat in the bottom, but measure the temperature at the top. This means that your valuable parts can get much hotter than you think. Top-Down Heating combined with our patented “Rate Control” system will protect your parts from overheating. J.R.’s Commercial Cleaning has customers that successfully clean copper and aluminum parts without damage.

What are Burn-off Ovens used for?

Burn-off ovens, also known as Heat-Cleaning Ovens, are used to remove organic materials such as paint, powder, plastic, and varnish from metal parts. They are frequently used to clean paint line fixtures plastic processing tooling, and for stripping electric motor cores before rewinding. Most applications recycle valuable parts and tooling.

Can I process aluminum parts in a Burn-off Oven?

Yes, as long as the aluminum is not too close to the combustion chamber where the heat enters the oven. J.R.’s Commercial Cleaning Burn-off oven has an exclusive, patented heating method called Top-Down Heating that controls the hottest spot in the oven. All other ovens have the combustion chamber in the bottom and control temperature at the top, so the hottest spot in the oven is not controlled.